CHP Power Plant

Waste 2 Energy

Best innovative, profitable and environmentally friendly concept

Waste2Energy - Plants (waste incineration with energy recovery) thermally treat household and

similar waste (e.g. tires) that remains after waste prevention and recycling –

generating energy from it. This energy can be in form of steam, electricity or hot water.

Waste2Energy - Electricity is fed into the grid and distributed to the end-users.

Hot water can be sent to a nearby district heating (or cooling) network to heat (or cool)

homes, hospitals, offices, cold stores, public buildings etc.,

and steam can be used by nearby industry in production processes.

Waste2Energy - is

➢ helping to reduce dependence on fossil fuels imports

➢ saving millions of tonnes of CO2

➢ helping with the realisation of „The National Climate Change Strategy“

➢ contributing to security of energy supply

➢ sustainable, local, low carbon, cost-effective and reliable energy

➢ helping to divert waste from landfills

Waste2Energy – content in 1 tonne municipal waste calorific value

➢ of 1 tonne brown coal

➢ or 0.330 tonnes hard coal

➢ or 250 litres oil.

Waste2Energy – contains in 1 tonne of bottom ash (after burning the waste)

100 – 150 kg metals including 15 to 20 kg aluminium ready for reusing in new products.

Waste2Energy - is clean and safe, plants are equipped with sophisticated filtering devices to deal with

the pollutants that are in the waste and minimise emissions into the atmosphere.

Waste2Energy - Plants contribute to achieving a recycling society and to improving countries resource

Efficiency, by using unavoidable waste as a valuable resource wherever possible.

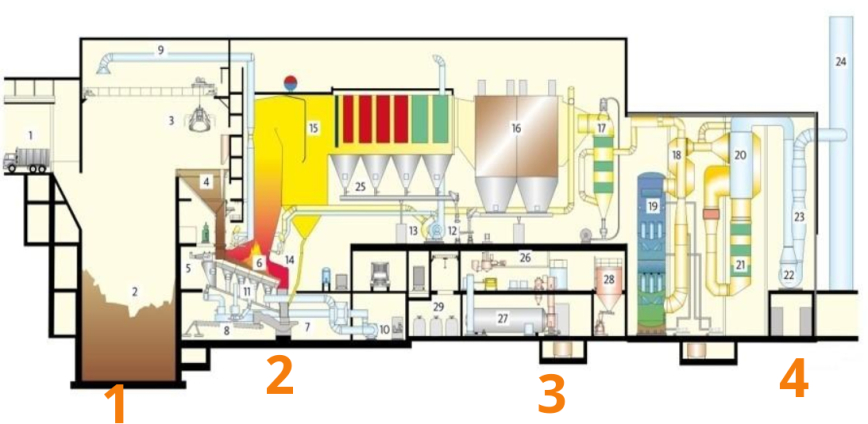

Components

1. Waste Combustion

The grate transports the waste through the combustion chamber. The waste is thus also mixed and burns out completely.

Unburnable material is left as bottom ash at the end of the grate. Metals and construction materials can be recovered from

this bottom ash and returned to the material cycle, thereby saving other raw materials

2. Energy recovery

The boiler recovers over 80% of the energy contained in the and makes it usable as steam.

3. Flue Gas Cleaning

Highly sophisticated processes assure that all pollutants contained in the waste and transferred into the flue gas

through combustion are eliminated in an efficient, sustainable and reliable way.

4. Energy - turbine, generator

The energy recovered is usableas electricity and/or heat (e.g. District Heating and Cooling, Industrial Processes). Roughly

half of the energy produced is renewable because it comes from the carbon-neutral biogenic fraction of waste.

A global need

Proper waste disposal combined with energy production is a global need. Our integrated solutions help to ensure a

clean, healthy and prosperous environment by enabling the environmentally sound disposal of municipal solid and

biological waste and simultaneous energy generation.

Worldwide, the amount of waste is growing faster than its population due to increased urbanization and economic

growth. Corresponding to the World Bank Report 2012, in 2025 the production of municipal solid waste was will be

Solve globalwaste problems

2.2 billion tones worldwide. With this amount, we are more and more polluting our own environment. Seven to

eight percent of the total greenhouse gas emissions arise from continued landfilling. Our Waste 2 Energy (W2E)

is the state of the art solution for this global problem. It is reliable and proven in hundreds of plants worldwide.

Protect the nature

W2E does not only decrease the volume of waste, it also protects natural resources like land and water. There

is no additional need for landfills, where leakage can occur and pollute our tap water. It also protects air and

climate because we improve on all current regulations by law. W2E plants decrease the greenhouse gases

which come from landfill. Finally the energy from waste process fights the deforestation. Waste is a locally

available fuel in all populated and industrialized areas.

Dont ́t waste the waste

it ́s your cheapest raw material and energy resource

Settlement plan

From idea to implementation it is a long way.

We are working in 4 phases each with the best available project partners.

We are as the general contractor for our customers their consulter and coodinator.

In this position we are completely independently in the election of project partners.

So we can donate the highest benefit for our clients.

Phase 1 Basis for decisions

- feasibility studies

- profitability analysis

- technical concepts

- process evaluations

- energy analysis

- environmental reports

- operation analysis

- risk analysis

- studies for plant optimization

Phase 2 Planning

- configuration of process engineering

- overall system planning

- cost and budget planning

- scheduling

- permit applications

Phase 3 Realization

- overall project management

- creation submission documents, offer tests

- Contracts

- monitoring detail engineering, production

- quality control

- coordination interfaces and construction processes

- cost and schedule control

- coordination and supervision commissioning

- monitoring guarantee compliance

- creating final settlement

- plant optimization

Phase 4 Operations

- peration assistant

- plant operation

- operational optimization